Esaar International Pvt. Ltd. is one of India’s top Zinc Pyrithione Suppliers. We also export this product to Iran, the Middle East, Eastern Europe and other countries. TDS for our Pyrithione are stated below.

Copper Pyrithione Sodium Pyrithione 40% FPS Zinc Pyrithione Powder

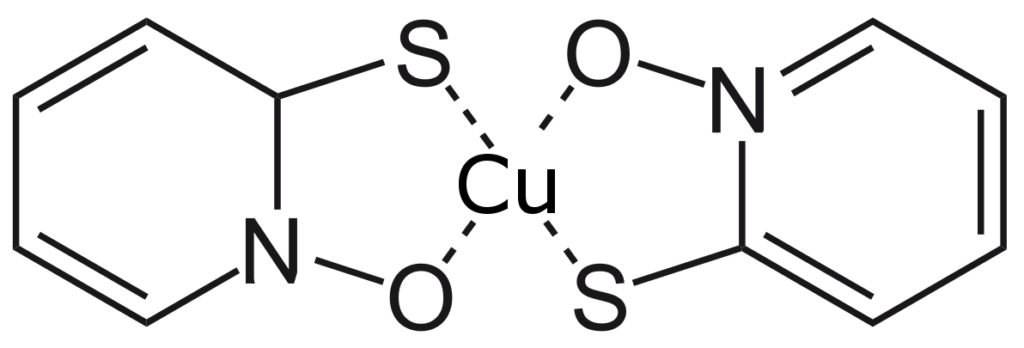

Copper Pyrithione

Description:

Copper Pyrithione Cu Powder is a light green crystalline type Fine Powder. It exhibits pronounced growth inhibiting activity against a broad spectrum of both Gram negative and Gram positive bacteria. Inhibits the growth of fungi, both yeast and mold. It is insoluble in water and inhibits the growth of algae. It is used as a marine antifouling agent. It is used in marine paints when a more gelling resistant antifoulant is required.

Features:

Copper pyrithione is intended to be used as a co-biocide (booster biocide) by both professional and non-professional users in antifouling products (PT 21) against marine fouling species. It is meant to be effective against soft-fouling organisms, so its function is to increase the efficacy of the product in order to remove the most problematic fouling organisms.

Functional Activity: Algaecide, Bactericide and Fungicide.

Guideline Application: Antifouling Paint in Marine and Yacht Applications. Controls Algae in Fishnet by coating..

Specification:

| Composition: | Micronised fine powder |

| Appearance: | Olive green coloured Powder |

| Odour: | Nearly odourless to Mild |

| Copper pyrithione: | 95% Min |

| Density: | 1.8106 at 22.5°C |

| Solubility: | Sparingly soluble in water 4.93 mg l-1 at 20.0°C; 6.11 mg l-1 at 30.0°C, Slightly improved solubility in organic solvents |

| Stability in product: | Light Stable, stable in the pH range 6-8 |

Antimicrobial efficacy: Copper Pyrithione Cu Powder possesses a broad spectrum of antifungal and Antialgal activity against all fungi and algae including following relevant organisms. This product can restrain and sterilize eight moulds, five bacteria, as well as two yeast fungis which are distillery yeast and bakers’ yeast. It’s MIC to various micro-organisms as follows:

| Microorganisms | MIC(PPM) | Microorganisms | MIC(PPM) | Microorganisms | MIC(PPM) |

| Aspergillus niger | 20 | Cladosporium herbarium | 6 | Escherichia coli | 8 |

| Aspergillus flavus | 20 | Trichoderma viride | 8 | Pseudomonas fluorescens | 18 |

| Aspergillus versicolor | 18 | Chaetomium globosum | 6 | Staphylococcus aureus | 6 |

| Penicillium citrinim | 8 | Bacillus subtilis | 8 | Saccharomyces cerevisiae | 6 |

| Pacillomyces varioti | 8 | acillus megaterium | 6 | Klocckeria Janke | 8 |

Application and Recommended Dosage: Copper Pyrithione Powder is a highly effective antifouling Agent for the control of hard fouling marine organisms such as seaweed and bacterial and diatom slimes. CPT is mainly used in anti-fouling marine paint, building coating, metal processing and pesticide fields. CPT and its like products have tremendous potential and broad space in pesticide field with properties of high-efficiency; environmental protection, hypo toxicity and broad-spectrum.It can be used in antifouling coatings to be applied on the underwater part of shipand boat hulls or static marine structures.

Benefits:

- Broad spectrum antimicrobial

- Excellent heat and pH stability

- No VOCs

- Low water solubility = low leach rate = long term protection

- Extensively tested toxicology and environmental profile

Normal addition levels are in the range 2 to 4 % by weight (on total formula, wet paint).

Handling of Copper pyrithion e Cu Powder: To avoids contact with eyes, skin and clothing. Upon contact with skin or eyes, wash off with water and seek medical advice. Remove contaminated clothing immediately and launder before re-use. Avoid all sources of ignition. Keep in dry & cool place and avoid direct sunlight.

Addition and compatibility: Chemical Stability and Compatibility

– Stable under ordinary conditions of use and storage

– Strong oxidizing agents to be avoided

– Tendency to8 self ignite above 80 Deg C.

Spillage/Disposal: Collect Spillage. Dispose of contents/container in accordance with local regulation

Packaging Details

• 20kg paper bags with two inner liner /Fiber Drums, Palletised and shrink wrapped, 4 – 5 MT per 20’FCL

Packaged by Esaar International Pvt. Ltd. – Copper Pyrithione Suppliers

Shelf Life

• 24 months from production date when stored at approximately 30°C

Storage

• Material should be stored in an enclosed area and away from direct sunlight and heat. Protect from extremes of temperature.

Delivery Time

Ex stock in the above packaging

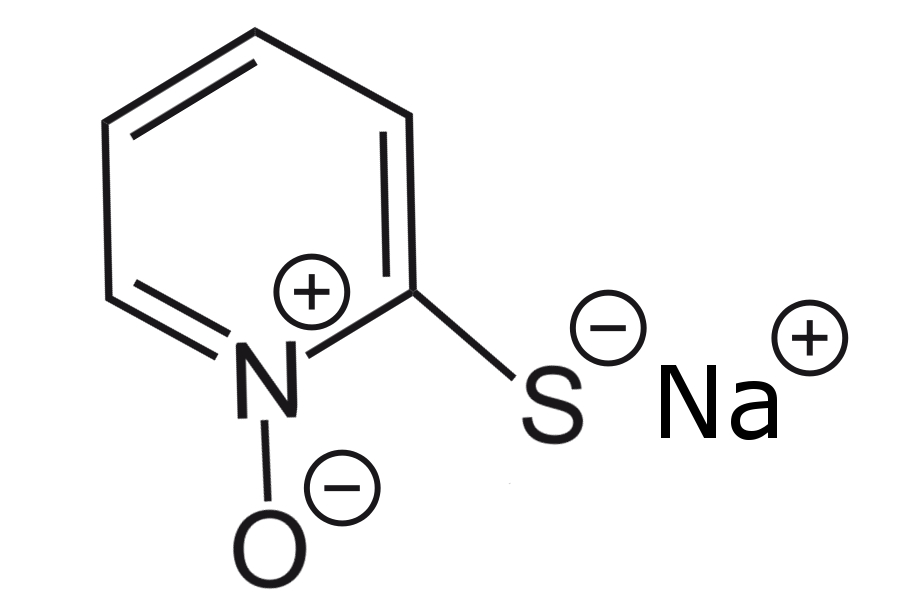

Sodium Pyrithione 40% FPS

Description: – Sodium Pyrithione is a widely used preservative for water based metal working fluids and as Mold and Midewcide in Gypsum Boards. Its activity spectrum provides for control of fungal growth. It is a highly effective microbiocide even at very low usage levels.

Product specifications:

| Composition: | A stable water based dispersion of Sodium pyrithione ( Sodium 2-pyridinethiol-1-oxide) |

| Appearance: | Dark yellow to amber brown solution |

| Sodium pyrithione | 40 to 42 % |

| pH ( neat) | 8.5 to 10.5 |

| Density (25°C): | 1.35 to 1.45 g/cm³ |

| Solubility: | Freely soluble in water |

| Refractive Index | 1.477 to 1.487 |

Antimicrobial efficacy: Sodium Pyrithione possesses a broad spectrum of antifungal and

Antialgal activity against all fungi and algae including following relevant organisms.

| MIC in ppm | |

| Bacteria | |

| Pseudomonas aeruginosa | 256 |

| Fungi | |

| Aspergillus niger | 128 |

| Fusarium sp | 256 |

| Cephalosporium | 64 |

Application and Recommended Dosage: Used as biocide (controls slime forming bacteria and fungi) in aqueous functional fluids (metalworking, cutting, cooling, and lubricating), latex emulsions (adhesives, caulks, patching compounds, sealants, pastes, and grouts), aqueous fiber lubricants and inks, jet-printer inks, laundry rinse additives and detergents, carpet cleaners, analytical and diagnostic reagents; Also used as in-can preservative for water based mixtures used in making concrete.

Application sites: In metalworking fluids, paints, inks, adhesives, plastics, laundry rinse additives, polymers, and floor finishes.

– Types and methods of application: For manufactured materials (i.e. plastics, paints, adhesives, etc.), to add at any point during the manufacturing process. As a preservative (i.e. in metalworking fluids and inks), add directly to the solution to be preserved.

Application /Dosage rates: For metalworking fluids, use 0.02 -0.06% of fluid; for inks, use 0.11 – 1.7% of of ink; for paints, use 0.22- 0.56% of of paint; for plastics and polymers, use 0.22 – 0.45% of plastic or polymer.

Handling of Kopthione Na: Where direct handling is necessitated, personnel should always wear protective clothing. This will include a rubber apron, suitable impervious full-length gloves and footwear. Protective chemical splash goggles should also be worn.

Addition and compatibility: Sodium Pyrithione is stable under normal environmental conditions if stored in closed, dark containers. At 100° C it is stable for 24 hours. In the light or in contact with weak oxidizing agents sodium pyrithione is converted to the disulfide, 2, 2-pyridyl-N-oxide disulfide. With stronger oxidizing agents or in alkaline solution (pH > 9.5) the substance is converted via a number of intermediates to the sulfonic acid.

Even alkalinity of metal working fluids is not affected by the addition of Sodium pyrithione. Compatible with most raw materials used in technical applications.

Spillage/Disposal: Spillages should be absorbed using an inert material such as vermiculite and

transferred to containers for disposal. Spillages should be disposed according to local regulations.

Packaging Details

• 25kg jerry cans or drums/200 kg plastic drums/1250Kg IBC

Packaged by Esaar International Pvt. Ltd. – Sodium Pyrithione Suppliers

Shelf Life

• 24 months from production date when stored at approximately 30°C

Storage

• Material should be stored in an enclosed area and away from direct sunlight and heat. Protect from extremes of temperature.

Delivery Time

• Ex stock in the above packaging

Transportation

• THIS MATERIAL IS NOT REGULATED AS A DOT HAZARDOUS MATERIAL

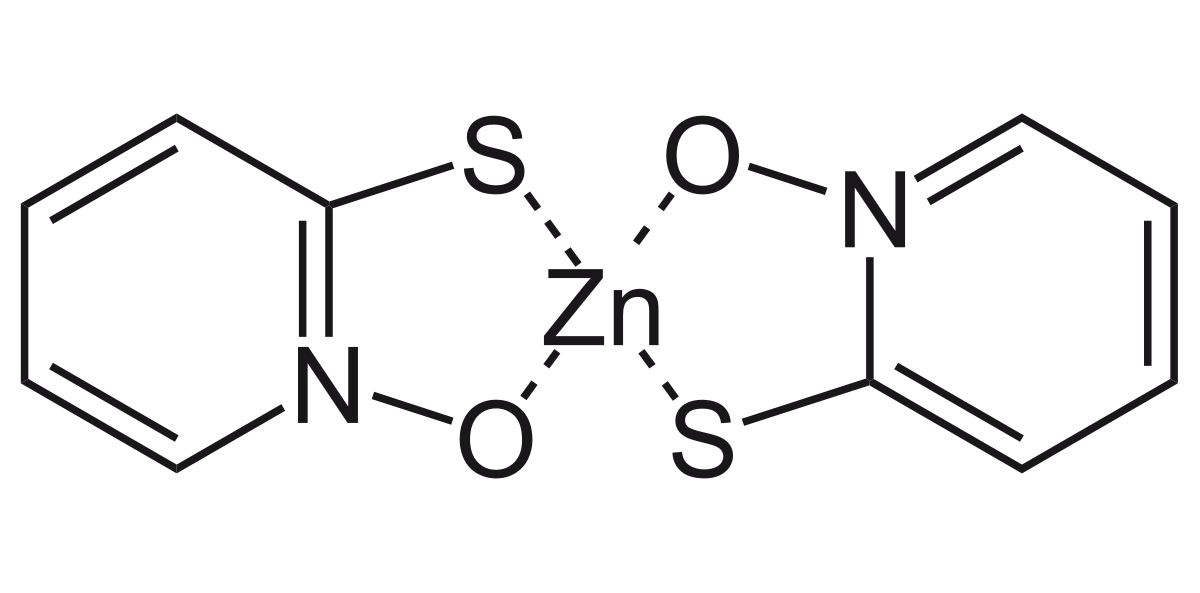

Zinc Pyrithione Powder

Description:

Zinc Pyrithione Powder is an off-white colour, micronized, industrial grade powder. It exhibits a significant growth inhibiting activity against a broad spectrum of both Gram-negative and Grampositive bacteria besides bacteria, Fungi, yeast and Mold. Its negligible solubility in water makes it a preferred biocide in Soft Fouling Marine paint applications Segment.

Features: A broad spectrum wet-state and dry film fungicide and algaecide to protect plastics, sealants, solvent and water borne textile coatings, wood coatings, lacquers, stains and emulsion paints from fungal and algal growth besides exhibiting good acteriostatic properties.

Product category: Dry Film Biocides for industrial applications.

Product application: As Antifungal agent in soft fouling Marine Paints, Sealants, Caulks, Grouts and patching compounds. Flooring Adhesives, Roofing ,Coated Fabrics, Wall covering and Leather cloth, Flexible Films, Foils and Sheet, Rigid Film, Sheet Extrusion and Injection Molding, Shoe uppers and Liners, Rubber Vulcanizations and Tyres.

Product industry: PVC, PU, Polyolefins, Adhesives & Water-based sealants, Inks and pigments, Polymers & Slurries, Building roducts, other applications, Coatings (dry-film biocides).

Product specifications:

| Composition: | Micronised powder of Zinc pyrithione ( Zinc 2-pyridinethiol-1-oxide) |

| Appearance: | Off White to beige coloured Powder |

| Odour: | Nearly odourless to Mild |

| Zinc pyrithione: | 97% Min |

| Density: | 1.8106 at 22.5°C |

| Solubility: | Sparingly soluble in water 4.93 mg l-1 at 20.0°C; 6.11 mg l-1 at 30.0°C, Slightly improved solubility in organic solvents |

| Stability in product: | Light Stable, stable in the pH range 3 – 10 |

Antimicrobial efficacy: Zinc Pyrithione Powder possesses a broad spectrum of antifungal and Antialgal activity against all fungi and algae including following relevant organisms.

| Bacteria | Algae | Fungi |

| Escherichia coli | Lyngbya sp. | Alternaria alternata |

| Micrococcus luteus | Plectonema gracillinum | Aspergillus niger |

| Proteus vulgaris | Scytonema stuposum | Curvularia lunata |

| Pseudomonas aeruginosa | Nostoc commune | Aureobasidium pullulans |

| Pleurococcus sp. | Chaetomium globosum | |

| Yeast | Scenedesmus sp. | Cladosporium sp. |

| Candida albicans | Anabaena sp. | Fusarium sp. |

| Saccharomyces cerevisiae | Chlorella | Pacillomyces sp. |

| Trebouxia sp. |

Application and Recommended Dosage: Zinc Pyrithione Powder is a highly effective antifouling Agent for the control of soft fouling marine organisms such as seaweed and bacterial and diatom slimes. It can be used in antifouling coatings to be applied on the underwater part of ship- and boat hulls or static marine structures. Generally it is used in combination with Cuprous oxide or Copper Thiocyanate as a booster biocide.

Potent Features:

– Displays potent antimicrobial activity towards fungi and algae and to a lesser extent bacterium.

– Zinc pyrithione inhibits the proton-linked ATPase in the fungal plasma membrane.

– Not consumed or degraded in the process of killing of micro-organisms.

– NR50 substance which can be used without environmental labelling below 2500 ppm.

– Product use level is dependent on the usage and application. Optimum use concentrations will depend on the required properties.

Normal addition levels are in the range 2 to 4 % by weight (on total formula, wet paint)

Handling of Zinc Pyrithione Powder: Avoid Dust Formation. Avoid contact with skin and Eyes. Where direct handling is necessitated, personnel should always wear protective clothing. This will include a rubber apron, suitable impervious full-length gloves and footwear. Protective chemical splash goggles should also be worn.

Addition and compatibility: – Chemical Stability and Compatibility.

-Hydrolytically stable between pH 4 and 8.5. Below pH 3.5 conversions to pyrithione occur. In alkaline solutions (pH >8.5) conversion to soluble alkali salts occurs.

-Transchelation in coatings occurs in the presence of heavy metal ions. Even traces of the corresponding chelates can cause a noticeable discolouration, foremost the iron and copper complexes.

-Sensitive to strong oxidizing and reducing agents and light.

– Photolytically stable in pigmented coatings.

Zinc Pyrithione can be added during one of the early stages of the paint manufacturing process, together with pigments and fillers.

Spillage/Disposal: Spillages should be absorbed using an inert material such as vermiculite and transferred to

containers for disposal. Spillages should be disposed according to local regulations.

Packaging Details

• 25kg paper bags with two inner liner /Fiber Drums, Palletised and shrink wrapped, 5 MT per 20’FCL

Packaged by Esaar International Pvt. Ltd. – Zinc Pyrithione Suppliers

Shelf Life

• 15 months from production date when stored at approximately 30°C

Storage

• Material should be stored in an enclosed area and away from direct sunlight and heat. Protect from extremes of temperature.

Delivery Time

• Ex stock in the above packaging